In modern construction and industry in the GCC region, electrical systems must withstand severe loads and extreme climatic conditions. Sandy winds, sudden overheating of equipment, constant dust all this creates additional risks for cables and connections. That is why trunking has ceased to be just a box for wires: it has become a key element of the infrastructure responsible for the safety, fire protection and durability of all electrical wiring. But in order for the system to work smoothly, you need to follow several strict rules.

Standards and Thermal Safety

The main rule is 45 percent. The internal space of the trunking cannot be filled with cables denser than this boundary. Ignoring it leads to overheating, insulation damage, and malfunction. The example shows this clearly: ten cables of 4 mm² each with a total cross-sectional area of 139 mm² require a minimum of 308.9 mm² of internal space. If we take the standard size of 50×25 mm, it gives about 1250 mm², and this not only corresponds to the norm, but also creates a reserve for future lines. Experienced engineers recommend adding another 25 percent for further connections, which eliminates the need to redo the route after a few years.

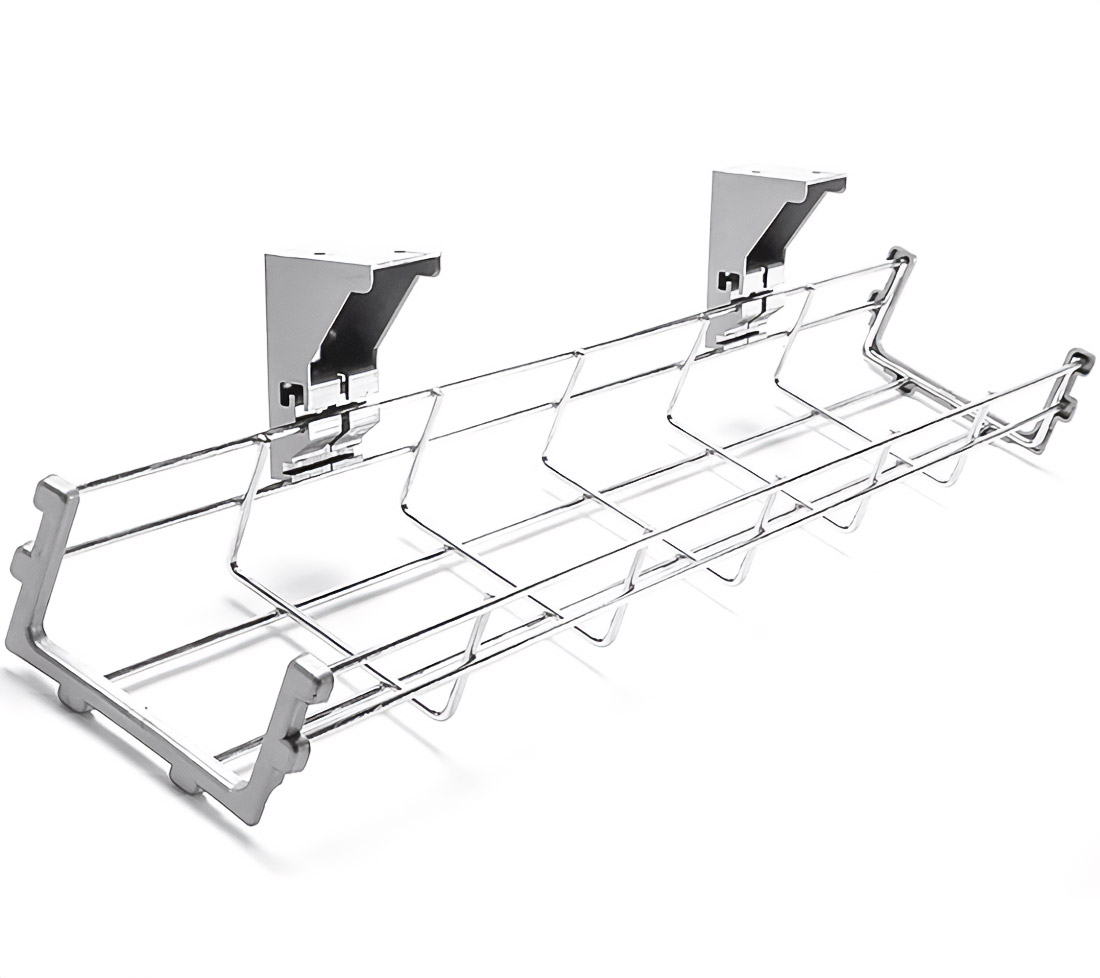

The materials are also selected strictly according to the operating conditions. In production halls and warehouse areas, galvanized steel is needed to protect against mechanical damage. In coastal areas or chemical installations, corrosion-resistant GRP is optimal. The IP rating is also important: IP54 is suitable for dry rooms, and IP65 is required for outdoor or areas with high humidity. These same environments also demand coordinated use of support elements such as cable tray accessories, since correct placement of trays and trunking directly impacts the stability and safety of installations.

Cable Separation and Grounding

The problem of electromagnetic interference remains one of the most acute. EMI easily disrupts Cat 6, Cat 7 and fiber optic lines if they are laid next to power circuits. The solution is multicomponent trunking or grounded metal partitions. When crossing trails, the 90-degree rule must be followed to minimize the impact of interference. Proper separation allows you to avoid data transfer rate drops and periodic outages, which are extremely difficult to diagnose in operation.

The grounding of the metal trunking is no less critical. Each section is connected by an earth continuity link, and the entire system is connected to the main grounding terminal of the switchboard. This approach turns trunking into a full-fledged protective guide. In the event of an accident, the leakage current immediately goes into the ground, and the protection device is triggered without delay.

The growth of the cable management market in the region confirms the trend. In 2023, it was estimated at 946.37 million dollars, and by 2032 it is projected to grow to 1,814.42 million. This reflects the need for certified components that ensure not only reliability, but also passage of inspections. In Dubai and Abu Dhabi, projects are regularly reviewed by DEWA and ADDC. At a load of about 400 kW, a substation with an 11 kV → 0.4 kV transformer is required. Moreover, criterion N-1 applies: two feeders via RMU must guarantee power for at least 6 hours if one fails.

Proper organization of cables is not a small detail, but the foundation of a secure infrastructure. Every factor is important here: the 45 percent rule, a 25 percent margin, separation by cable type, IP protection, certified materials, and proper grounding. Failure to comply with any point leads to delays at the project approval stage, expensive repairs and, most importantly, to a risk to people and equipment.

I am Administrative Assistant with eight years of experience working alongside the executive team.